1,5-Pentanediol serves as a valuable chemical in today’s manufacturing. This clear, colorless liquid has a molecular weight of 104.15 g/mol and stands out for its stability and high purity. Industries rely on its unique properties to create high-performance materials and efficient processes. In 2024, global production volumes surpassed 19,800 metric tons, with Asia-Pacific, North America, and Europe as major contributors. The following table shows how key sectors use this compound in coatings, adhesives, packaging, personal care, and pharmaceuticals:

| Sector | Description |

|---|---|

| Automotive | Major consumer utilizing bio-sourced 3-Methyl-1,5-Pentanediol in coatings, adhesives, and plasticizers for lightweight and durable materials. |

| Construction | Uses bio-sourced 3-Methyl-1,5-Pentanediol in paints, sealants, and flooring materials, driven by green building certifications. |

| Packaging | Adopts bio-sourced 3-Methyl-1,5-Pentanediol for flexible films, coatings, and adhesives, focusing on sustainability. |

| Personal Care | Gaining traction as a safe and sustainable ingredient in cosmetics and personal care products. |

| Pharmaceuticals | Utilized for its effectiveness and sustainability in various pharmaceutical applications. |

Key Takeaways

- 1,5-Pentanediol is a versatile compound used in various industries, including automotive, construction, and personal care, due to its stability and high purity.

- This compound enhances the performance of coatings and adhesives by improving flexibility, adhesion, and resistance to UV and chemicals.

- Manufacturers increasingly choose 1,5-Pentanediol for biodegradable plastics, supporting sustainability goals while maintaining high mechanical properties.

- Innovations in synthesis and production methods are making 1,5-Pentanediol more efficient and environmentally friendly, driving its market growth.

- Using 1,5-Pentanediol helps companies meet modern demands for high-performance materials while reducing their carbon footprint.

1,5-Pentanediol Properties

Chemical Structure

Chemists classify 1,5-Pentanediol as a linear diol with the molecular formula C5H12O2. The molecule contains two hydroxyl groups at the first and fifth carbon atoms. This structure allows the compound to participate in a wide range of chemical reactions. Manufacturers often use chemical methods that start with dimethylglutarate or biomass-derived materials such as furfural and tetrahydrofurfuryl alcohol. Some companies also use biosynthetic methods, where engineered Escherichia coli produce the compound from lysine. These diverse synthesis routes support large-scale production and help meet industrial demand.

Physical Characteristics

1,5-Pentanediol appears as a clear, colorless oily liquid. Its physical properties make it suitable for many industrial applications. The following table summarizes the most important characteristics:

| Property | Value |

|---|---|

| Density | 0.994 g/mL at 25 °C |

| Melting point | −18 °C |

| Boiling point | 242 °C |

| Solubility in water | Miscible |

These features enable the compound to blend easily with water and other solvents. Its high boiling point and low melting point provide stability in various manufacturing processes.

Safety and Storage

Safe handling and proper storage are essential in industrial settings. Companies should follow these guidelines:

- Keep containers tightly closed in a dry, well-ventilated place.

- Store in a cool location, as the substance is hygroscopic.

- Use eye and face protection that meets government standards.

- Wear gloves and impervious clothing to protect skin and body.

- Respiratory protection is not required for normal exposure, but specific respirators may be used for nuisance exposures.

The regulatory environment in the United States emphasizes chemical safety and environmental sustainability. Agencies such as the EPA require compliance with standards like the Toxic Substances Control Act (TSCA) and REACH. Manufacturers must conduct extensive testing and maintain documentation. Many companies also pursue green certifications to enhance market credibility.

Industrial Applications of 1,5-Pentanediol

Polyesters and Polyethers

Manufacturers use 1,5-Pentanediol as a key building block in the production of polyesters and polyethers. These polymers form the backbone of many high-performance materials found in textiles, packaging, and engineering plastics. Long-chain polyesters made from this compound show thermal and mechanical properties similar to polyethylene. The melting temperature often exceeds 70 °C, which means these materials can withstand higher temperatures during processing and use. As the chain length of the diacid increases, the resulting polyesters display enhanced crystallizability and tensile modulus. These features lead to improved strength and flexibility in finished products. Many companies choose 1,5-Pentanediol because it offers superior gas barrier performance compared to other biodegradable plastics like PBAT. This advantage makes it suitable for packaging that requires protection from moisture and gases.

Polyesters and polyethers produced with 1,5-Pentanediol help industries meet demands for durability, safety, and environmental responsibility.

Specialty Chemicals and Solvents

1,5-Pentanediol serves as a versatile intermediate in the synthesis of specialty chemicals and solvents. Its solvency power allows it to dissolve a wide range of organic compounds, making it valuable in industrial cleaning agents and formulations. The following table highlights common applications:

| Application Type | Description |

|---|---|

| Polyurethanes | Used as a raw material for polyester polyols to modify polyurethane elastomers, enhancing mechanical properties. |

| Unsaturated Polyesters | Improves alkali resistance and adhesion in resins, used in wires and cables for insulation. |

| Plasticizers | Exhibits excellent properties for plastics, rubber, and epoxy resins, enhancing performance. |

| UV-Curable Coatings | Key ingredient for coatings with low viscosity and fast curing speed, used in high-quality inks. |

| Fragrance Synthesis | Used to synthesize Musk 105, providing an elegant musk aroma. |

| Cosmetics | Functions as a moisturizer and solvent in various personal care products. |

| Brake Fluid | Acts as an additive in brake fluids. |

| Cutting Oil and Detergents | Serves as a solvent in cutting oils and special detergents. |

| Pharmaceutical Intermediates | Used in the synthesis of drug intermediates like Pseudomonic Acid D Sodium. |

Industries such as coatings, adhesives, and textiles drive the market for pentanediol. These sectors seek high-performance and environmentally friendly solutions, which increases demand for this compound. Its low volatility and stability help control drying times and film formation in coatings. As an intermediate in organic synthesis, 1,5-Pentanediol improves product quality and consistency across a wide range of applications.

Polyurethane Chain Extenders

Polyurethane manufacturers rely on 1,5-Pentanediol as a chain extender to enhance the properties of their products. This compound improves elongation, tear strength, and resistance to chemicals and weathering. When used in the polymer backbone, it provides flexibility and good impact resistance. These qualities are crucial for industrial applications such as automotive parts, construction materials, and protective coatings. The improved performance of polyurethane materials helps companies deliver products that last longer and perform better under stress.

- 1,5-Pentanediol acts as a building block for polymers, making it essential in organic synthesis.

- Its effectiveness in coatings and adhesives comes from its unique chemical structure.

- The compound’s stability and solvency power support its use in industrial cleaning agents and specialty formulations.

By serving as a reliable intermediate, 1,5-Pentanediol enables manufacturers to create advanced materials that meet modern industry standards.

1,5-Pentanediol in Coatings and Adhesives

Coatings and adhesives play a vital role in protecting surfaces and joining materials in manufacturing. Companies seek solutions that deliver durability, flexibility, and sustainability. 1,5-Pentanediol meets these needs by enhancing the performance of both waterborne coatings and adhesive formulations.

Waterborne Coatings

Manufacturers use waterborne coatings to reduce volatile organic compounds and improve workplace safety. 1,5-Pentanediol strengthens these coatings in several ways:

- Improved Flexibility and Impact Resistance: The compound increases polymer chain mobility. Coatings can withstand deformation without cracking.

- Enhanced Adhesion: It promotes better wetting and adhesion to many substrates. This ensures long-term performance on metals, plastics, and composites.

- UV and Chemical Resistance: The chemical structure of 1,5-Pentanediol helps coatings resist degradation from UV radiation and harsh chemicals. This extends the lifespan of painted surfaces.

Urbanization and infrastructure development drive demand for durable coatings. Products containing pentanediol perform well in challenging environments. The shift toward sustainable materials encourages innovation in eco-friendly formulations. Pyran’s bio-based 1,5-Pentanediol reduces greenhouse gas emissions, supporting sustainability and improving the durability of paints and adhesives.

Adhesive Formulations

Adhesives must bond surfaces securely and resist wear over time. 1,5-Pentanediol enhances adhesive formulations by improving several key properties:

| Property Enhanced | Description |

|---|---|

| Flexibility | The linear five-carbon chain provides flexibility, improving the elasticity of the polymers. |

| Toughness | Enhances toughness, contributing to better mechanical performance in adhesive formulations. |

| Reduced Crystallinity | Lowers crystallinity in polyester polyols, allowing for better application in foams and coatings. |

| Moisture Retention | Functions as a humectant, retaining moisture and preventing premature drying in adhesives. |

| Adhesion | Improves adhesion properties, enhancing the performance of coatings and adhesives. |

| Resistance to Cracking | Increases resistance to cracking or peeling, particularly in automotive and industrial finishes. |

| Bio-based Crosslinker | Its diacrylate derivative serves as a renewable alternative in UV-curable coatings and inks. |

The use of renewable feedstocks for producing 1,5-Pentanediol aligns with sustainable practices. Manufacturers benefit from improved product performance and durability. As industries continue to innovate, pentanediol remains a preferred choice for advanced coatings and adhesives.

Plastics and Polymers

Biodegradable Plastics

Manufacturers increasingly choose 1,5-Pentanediol for developing biodegradable plastics. This compound helps create copolyesters that break down quickly in natural environments. The unique structure of 1,5-Pentanediol allows it to form strong ester linkages, which support both flexibility and biodegradability. When used in thermoplastic elastomers, it delivers impressive mechanical properties and resilience. The following table highlights key features of these biodegradable plastics:

| Property | Description |

|---|---|

| Resilience | Shape recovery ratio exceeds 70% at 200% strain. |

| Mechanical Strength | Elongation at break surpasses 1200%, showing excellent flexibility and toughness. |

| Thermal Stability | Maintains stability under heat, suitable for various applications. |

| Biodegradability | Achieves complete mass loss after 6 days in enzyme solution at 37 °C, confirming rapid breakdown. |

These characteristics make 1,5-Pentanediol-based plastics ideal for packaging, agricultural films, and disposable products. Companies value the ability to produce materials that perform well and decompose efficiently, supporting sustainability goals.

Specialty Polymers

1,5-Pentanediol plays a vital role in synthesizing specialty polymers. Its hydroxyl groups at both ends of a five-carbon chain enable the formation of ester linkages, which are essential for creating high-performance polyester and polyether resins. These specialty polymers offer a balance of flexibility, moderate glass transition temperatures, and strong mechanical properties. Manufacturers use them in several applications:

- Cellulose-based products

- Adhesives

- Coatings

- Poly(1,5-pentylene terephthalate) (PPeT)

Poly(1,5-pentylene terephthalate), or PPeT, stands out as a flexible terephthalic polyester. Producers synthesize PPeT from terephthalic acid and biobased pentanediol. This polymer features a lower glass transition temperature than common terephthalic polyesters, which increases its flexibility and durability. Specialty polymers made with 1,5-Pentanediol also serve as plasticizers, emulsifying agents, and resin intermediates. These materials enhance the performance of coatings, adhesives, and textiles. In polyurethane production, 1,5-Pentanediol acts as a chain extender and solvent, improving flexibility and strength in foams, coatings, and elastomers.

Manufacturers rely on 1,5-Pentanediol to create advanced plastics and polymers that meet modern standards for performance and sustainability.

Comparison with Alternatives

Performance Benefits

Manufacturers often compare 1,5-Pentanediol with other diols such as 1,3-propanediol and 1,4-butanediol. Each diol offers unique advantages in industrial applications.

- 1,5-Pentanediol acts as a bio-based monomer in polymers, coatings, and plasticizers.

- It serves as a sustainable alternative to petroleum-based diols like 1,6-hexanediol.

- Production of 1,5-Pentanediol can reach high efficiency, with productivity up to 8.9 mmol per catalyst per hour under solvent-free conditions.

- Other diols, such as 1,3-propanediol and 1,4-butanediol, also come from renewable resources and support green manufacturing.

These features make 1,5-Pentanediol a strong choice for companies seeking high performance and efficiency.

Sustainability Impact

Sustainability remains a top priority for many industries. 1,5-Pentanediol stands out for its environmental profile.

- Lifecycle assessments show that 1,5-Pentanediol can reduce greenhouse gas emissions by up to 99% compared to petroleum-based diols.

- The compound comes from a commercially established feedstock and meets regulatory standards such as TSCA and REACH.

- An ISO-certified lifecycle assessment supports its green credentials.

Companies that use 1,5-Pentanediol help lower their carbon footprint and meet global sustainability goals.

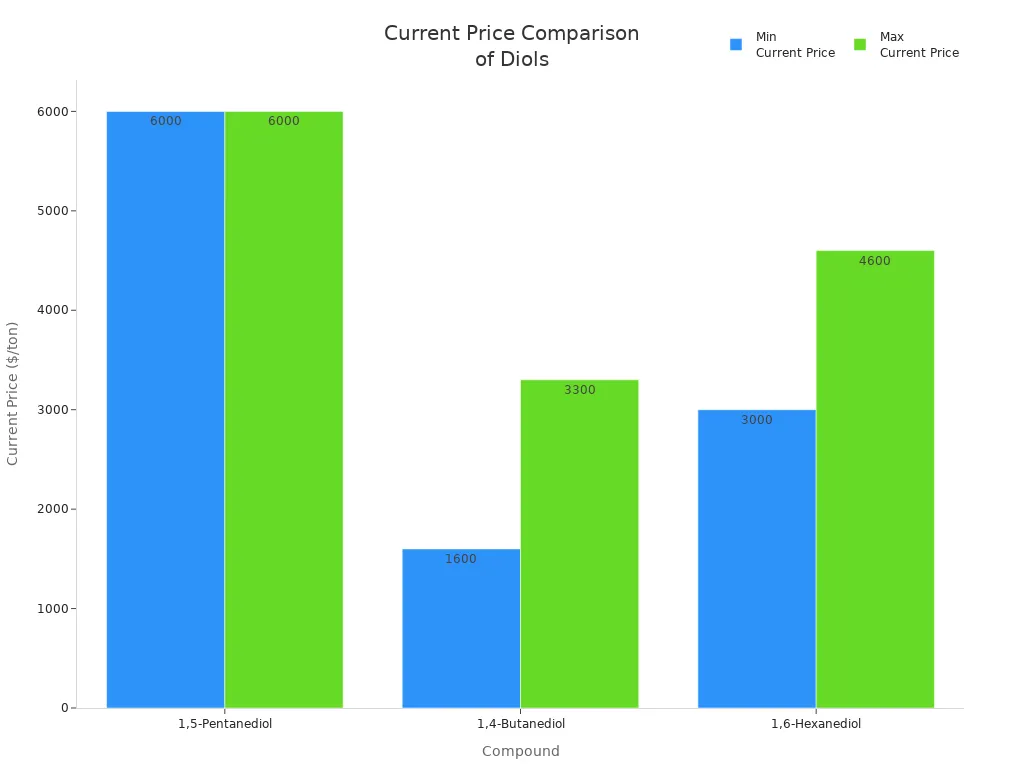

Economic Factors

Cost plays a key role in material selection. The table below compares the current prices of 1,5-Pentanediol and its main alternatives:

| Compound | Current Price ($/ton) | Competitive Price ($/ton) | Market Growth Rate | Annual Market Size ($) |

|---|---|---|---|---|

| 1,5-Pentanediol | 6000 | 1140 | 7% | 7 billion |

| 1,4-Butanediol | 1600–3300 | N/A | N/A | N/A |

| 1,6-Hexanediol | 3000–4600 | N/A | N/A | N/A |

1,5-Pentanediol commands a higher price due to its advanced properties and sustainable production. Its market continues to grow, driven by demand for high-performance and eco-friendly materials.

Future Trends

Innovations in Synthesis

Researchers continue to advance the synthesis of 1,5-Pentanediol to meet the needs of modern manufacturing. Recent developments focus on improving efficiency and sustainability. Many companies now use bio-based feedstocks, which help reduce environmental impact. Scientists have introduced new catalytic processes that increase yield and lower production costs.

- Highly efficient catalysts now support selective hydrogenation of furfural, a key step in producing 1,5-Pentanediol.

- Research teams are developing non-precious metal-based bifunctional catalysts. These alternatives help make large-scale production more affordable.

- Digitalization and automation have become important in manufacturing. These technologies optimize workflows and improve consistency.

- Process engineers work to overcome challenges in achieving high selectivity from furfural. They explore new reaction pathways and catalyst designs.

Many of these innovations aim to expand raw material sourcing and unlock new applications for 1,5-Pentanediol in advanced manufacturing.

Market Outlook

The market for 1,5-Pentanediol shows strong growth potential over the next decade. Several factors drive this trend. Industries such as automotive, construction, and electronics continue to increase their use of high-performance materials. Companies also shift toward sustainable practices, which boosts demand for bio-based chemicals. Ongoing research and development open new opportunities in pharmaceuticals and specialty chemicals.

| Year | Market Value (USD) | CAGR (%) |

|---|---|---|

| 2023 | 200 million | N/A |

| 2032 | 400 million | 8 |

The Asia Pacific region is expected to lead market growth, with countries like China, India, and Japan investing in industrialization and urbanization. North America remains important due to its advanced automotive and electronics sectors. Europe is projected to grow steadily as well.

- Main drivers include the need for sustainable products, rising demand in key industries, and new applications in advanced manufacturing.

- Some challenges remain, such as strict regulations and raw material price volatility.

The future for 1,5-Pentanediol looks promising as innovation and market demand continue to rise.

1,5-Pentanediol supports many industries by improving product quality and efficiency. The table below highlights its main uses and benefits:

| Application Area | Advantages |

|---|---|

| Polymer Manufacturing | Enhances properties such as flexibility, durability, and chemical resistance. |

| Coatings | Important for maintaining production efficiency and product competitiveness. |

| Adhesives | Facilitates efficient chain extension and cross-linking in formulations. |

Looking ahead, several trends will shape its role in manufacturing:

- Bio-derived production methods offer renewable alternatives.

- Continuous processes help scale up and reduce waste.

- Industry 4.0 tools, like IoT and AI, improve process control.

- New catalysts boost yield and lower environmental impact.

- Green chemistry creates safer, more sustainable products.

1,5-Pentanediol will continue to drive innovation and sustainability in specialty chemicals.

FAQ

What is 1,5-Pentanediol used for in industry?

1,5-Pentanediol finds use in manufacturing polyesters, polyethers, specialty chemicals, and polyurethane chain extenders. Many companies also use it in coatings, adhesives, and biodegradable plastics.

Is 1,5-Pentanediol safe to handle?

Workers should follow standard chemical safety protocols. They should wear gloves, eye protection, and impervious clothing. Companies should store the product in a cool, dry place.

How does 1,5-Pentanediol support sustainability?

Many manufacturers produce 1,5-Pentanediol from renewable resources. This process reduces greenhouse gas emissions and supports green manufacturing goals.

Can 1,5-Pentanediol improve product performance?

Yes. 1,5-Pentanediol enhances flexibility, durability, and chemical resistance in polymers, coatings, and adhesives. It helps companies meet high-performance standards.

Where can companies purchase 1,5-Pentanediol?

Companies can contact chemical suppliers like Leichi Chem for bulk or sample orders. The supplier provides support and ensures compliance with industry regulations.

Post time: Jan-27-2026