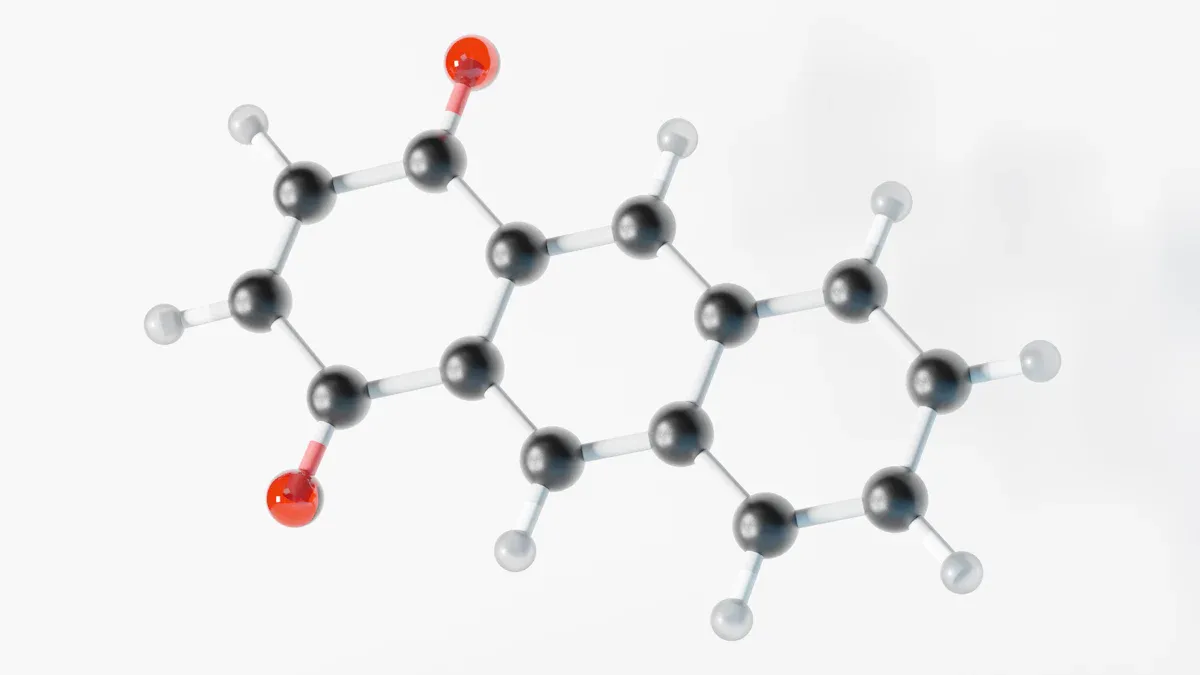

Pharmaceutical intermediates are the chemical building blocks created during drug synthesis. These compounds, such as 5-bromo-1-cyclopropyl-4-fluoro-1H-indazole CAS NO. 2490501-34-1, form a step-by-step pathway to the final active pharmaceutical ingredient (API).

The rising global demand for innovative drugs and therapies is a key driver for this industry’s expansion.

This growing need fuels significant market growth, as projected below.

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2024 | 33.37 | - |

| 2029 | 46.04 | 7.1 |

Key Takeaways

- Pharmaceutical intermediates are important building blocks. They help make complex drugs in steps. This makes drug creation easier and safer.

- Intermediates help make drugs faster and with less waste. They allow chemists to build drugs piece by piece. This saves money and helps the environment.

- Intermediates ensure drugs are safe and work well. Each step is checked for quality. This stops bad chemicals from getting into the final medicine.

The Role of Pharmaceutical Intermediates in Drug Synthesis

Pharmaceutical intermediates are much more than simple stepping stones. They are strategic tools that chemists use to make drug synthesis practical, efficient, and safe. By breaking down the creation of a complex drug into a series of manageable stages, these compounds play a vital role in modern medicine.

Simplifying Complex Chemical Recipes

Think of synthesizing a complex drug as following an intricate, multi-page recipe. Trying to do everything at once would be chaotic and likely end in failure. Intermediates allow chemists to complete one part of the recipe perfectly, purify it, and then move on to the next. This approach relies on two main strategies:

- Building Block Strategy: Chemists use pre-made, well-understood fragments (intermediates) and assemble them. This simplifies the overall chemical pathway and reduces the number of steps needed from scratch.

- Convergent Strategy: Multiple intermediates are created separately and then combined in a final step to form the drug. This method is often faster and results in a higher overall yield compared to building a molecule one atom at a time in a long, linear chain.

Many of today’s most advanced medicines, especially large-molecule biologics, depend on these multi-step pathways. Each step produces a specific intermediate that becomes the starting point for the next, ensuring the final product is built correctly.

| Drug Name | Key Synthesis Steps |

|---|---|

| Insulin | The human insulin gene is first placed into bacteria or yeast. These microorganisms produce a precursor called proinsulin (an intermediate). The proinsulin is then harvested, purified, and enzymatically cut to create active insulin. |

| Monoclonal Antibodies (mAbs) | Genes for the antibody are inserted into mammalian cells. These cells are grown in large bioreactors to produce the antibody. The antibody is then harvested and purified through multiple chromatographic steps, with each purified stage representing an intermediate state. |

| Conjugated Vaccines (e.g., Prevnar 13) | Polysaccharides from bacteria and a carrier protein are produced separately as intermediates. These two components are then chemically linked (conjugated) and purified to create the final vaccine. |

Improving Manufacturing Efficiency

In large-scale drug production, efficiency is key to keeping costs down and meeting global health needs. Using well-designed pharmaceutical intermediates directly improves manufacturing efficiency in several ways. By optimizing the synthesis route, manufacturers can increase yields, reduce waste, and shorten production timelines.

This focus on efficiency aligns with the principles of “Green Chemistry.” One important metric is the E-factor (environmental factor), which measures the amount of waste generated per kilogram of product. A lower E-factor means a more efficient and sustainable process. Designing synthesis routes with high-yield intermediates helps minimize waste and lower the E-factor.

Technology is also accelerating this process. For example, the company Evonik used Artificial Intelligence (AI) and continuous flow chemistry to speed up experimentation cycles by 50–100 times. An AI-driven system adjusted reaction conditions in real-time, dramatically reducing development timelines for new intermediates and drugs.

Ultimately, intermediates boost efficiency by:

- Allowing companies to outsource intermediate production to specialized, cost-effective manufacturers.

- Enabling the “telescoping” of reaction steps, where multiple transformations occur in a single operation without isolating each intermediate.

- Creating intermediates that crystallize easily, which simplifies purification and avoids costly and time-consuming chromatography steps.

Ensuring Drug Safety and Quality

The quality of a final drug is entirely dependent on the quality of its building blocks. Even tiny impurities or structural errors in an intermediate can lead to a final product that is ineffective or, worse, harmful.

One of the most important aspects of quality is stereochemistry—the precise 3D arrangement of atoms in a molecule. Many drug molecules are “chiral,” meaning they exist in two forms that are mirror images of each other, like a left and right hand. Although they look similar, the body can tell them apart. One version (enantiomer) might provide the therapeutic benefit, while the other could be inactive or cause dangerous side effects. For instance, the body’s β1-adrenergic receptor binds to the (R)-propranolol version 100 times more tightly than its (S)-mirror image, making it effective for hypertension. Using intermediates with the correct stereochemistry is essential to produce only the safe, active version of the drug.

Controlling impurities is another critical safety measure. If impurities are not removed at an intermediate stage, they can be difficult or impossible to remove from the final API.

A famous example involves the blood pressure drug valsartan. In 2018, recalls were issued after batches were found to be contaminated with N-nitrosodimethylamine (NDMA), a probable human carcinogen. Investigators traced the contamination back to a change in the manufacturing process of a key chemical intermediate.

To prevent such incidents, regulatory bodies like the International Council for Harmonisation (ICH) have strict rules (such as ICH Q7 and Q11) for intermediate manufacturing. These rules require:

- Controlled production environments.

- Validated processes to control and remove impurities.

- Complete traceability of all materials.

Companies use a variety of advanced techniques to purify intermediates and test their quality. Purification methods like Preparative HPLC and Supercritical Fluid Chromatography (SFC) are used to remove unwanted byproducts. Afterward, analytical tests are performed to confirm the intermediate’s identity, purity, and quality before it moves to the next step.

- Structural Tests: NMR Spectroscopy and Mass Spectrometry confirm the molecule’s structure is correct.

- Purity Tests: HPLC and Gas Chromatography (GC) detect and measure any impurities.

- Trace Metal Tests: ICP-MS is used to find tiny amounts of metal impurities, often from catalysts.

By isolating, purifying, and rigorously testing each intermediate, manufacturers ensure that only the correct, high-quality material proceeds in the synthesis. This step-by-step quality control is fundamental to producing the safe and effective medicines we rely on.

The Step-by-Step Journey from Intermediate to API

The creation of a drug is a carefully planned sequence of chemical reactions. Each step builds upon the last, transforming simple chemicals into a complex, life-saving medicine. This journey relies on the creation and modification of pharmaceutical intermediates.

Step 1: Creating the First Building Block

The process starts with basic raw materials. Chemists select simple organic and inorganic compounds to begin the synthesis.

- Organic materials: Benzene, alcohols, and amino acids.

- Inorganic materials: Mineral acids and metal salts.

Chemists use specific reactions like nitration or Friedel-Crafts acylation to combine these starting materials. For example, the synthesis of paracetamol begins by reacting benzene with nitric acid. This reaction creates the first key intermediate, nitrobenzene, which serves as the foundation for the next steps.

Step 2: Modifying the Intermediate Structure

Once the first intermediate is created and purified, chemists begin modifying its structure. This involves a series of reactions that add, remove, or change functional groups. For instance, an alcohol group might be converted into an ester, or an amine group might be added. Each modification brings the molecule closer to the final drug structure.

Scientists carefully tailor a molecule’s structure to improve its ability to fight a virus. This can make the drug more powerful or help it overcome resistance from viral mutations.

After each modification, the new intermediate is purified using methods like chromatography to remove any unwanted byproducts.

Step 3: The Final Transformation into a Drug

The last step converts the final, highly refined intermediate into the active pharmaceutical ingredient (API). This final reaction is critical and often presents challenges when scaling up from a lab to a factory. Controlling heat and ensuring purity are major hurdles, as even tiny impurities can become significant problems in large batches. Once the reaction is complete, the API is carefully isolated and purified, making it ready for formulation into a pill, injection, or other form of medicine.

Pharmaceutical intermediates are the purified building blocks that make drug synthesis manageable, scalable, and safe. These compounds are the unsung heroes in the journey from a chemical concept to a life-saving medicine. They enable the reliable and efficient production of the drugs that millions of people depend on daily.

Post time: Dec-04-2025